GHG Reduction Revenue

Wormarvel’s groundbreaking capabilities bring an enormous positive change to the existing waste treatment market, reducing GHG and environmental services approach. There is a high potential to develop and get the new products and services provided by Wormarvel into the global market. Accordingly, the company is looking for substantial funding to support its final stages of technology development, as well as its business development, for scaling-up the distribution to the European market. This innovative concept contributes significantly to the reduction of GHG and adds tax revenue for this reduction.

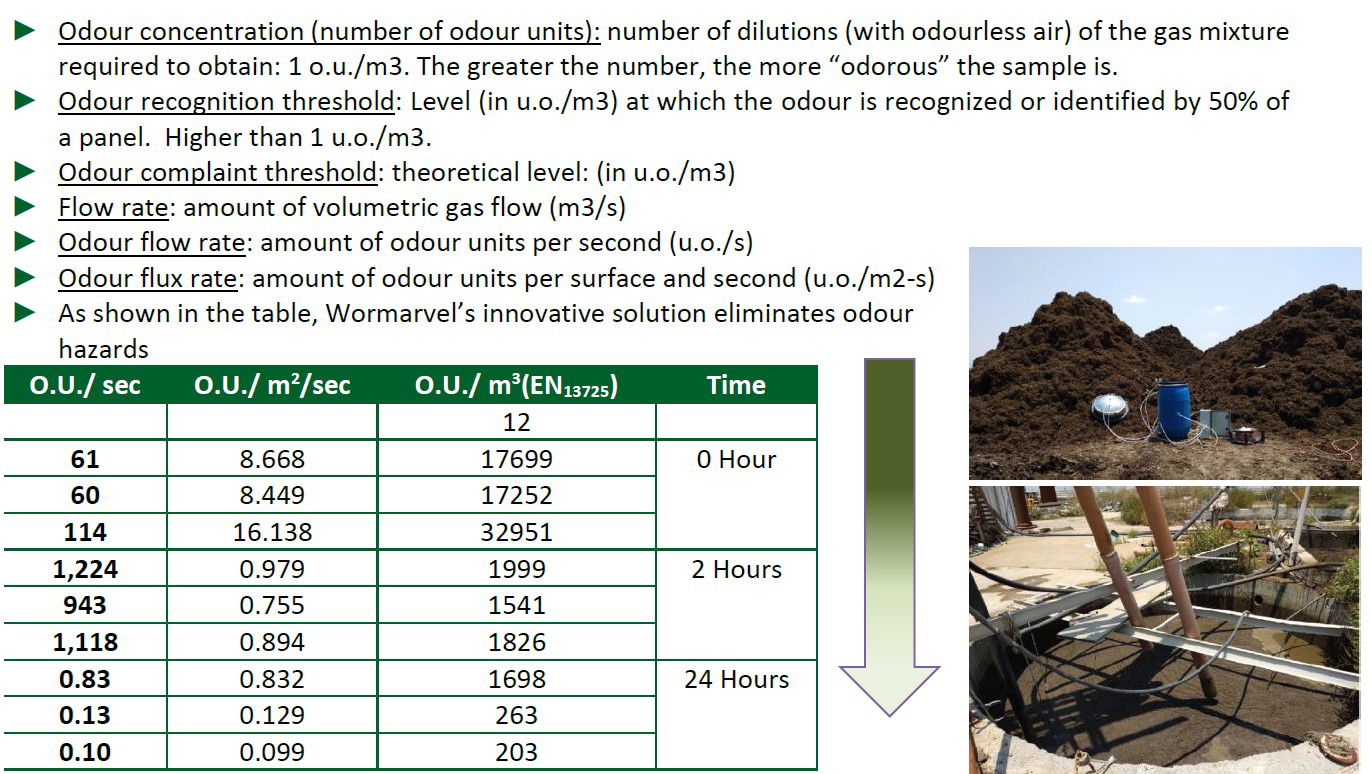

GHG emission starts rapidly when fresh organic matter is accumulated. Our system is an instant and continuous slurry treatment that prevents bacteria accumulation, reduces emission, and avoids the need for pig slurry storage and, in limited seasons, land application.

Separation of solids from slurry liquids allows the best treatment to reduce GHG, separately for each liquid and solids.

Earthworms have a clear effect on gaseous emissions during the Vermifiltration of fresh pig slurry. The high earthworm population is associated with a methane sink, the absence of ammonia emissions, and reduced nitrous oxide emissions

Wormarvel's breeding system achieves a significantly high earthworm population during all year seasons, compared to any other worms breeding system.

The Bio-Humus (Vermicompost) production's test results indicated that earthworms reduce CH4, N2O, and NH3 emissions respectively by 72.63–99.99%, 99.68%–99.91%, and 82.30–89.92%, compared with conventional composting.

Earthworms are a bioindicator to certify low greenhouse gas and ammonia output in systems using fresh slurry.

Our novel innovative idea is eliminating in one system the negative side associated with insufficient recycling resource depletion and pollution of Air (GHG emission), Water, Soil in pig's production.

.